Concern about waste and pollution has increased dramatically in recent years. Underlying most governmental effort to reduce it is the idea of a circular economy, which essentially means waste minimisation through recycling.

The idea has also received criticism. The true economic and environmental costs of recycling have sometimes been concealed by subsidies. Recycling working conditions are often poor (manual sorting of domestic waste, for example), and “circular economy rebound” occurs if increased material supplies lead to lower prices, inflating demand.

Sustainable consumption

It’s clear that current thinking about sustainability has far to go. It is an illusion if the labour and energy to reuse old “stuff” exceeds that of creating new ones, or if it replaces skilled artisans with unsanitary minimum wage labour. If consumption continues to be fuelled by fiscal “capital” that is not generated by genuine material production, environmental benefits can never materialise.

Having said that, circular economics work extremely well in particular contexts, and one of them is the production of durable, reusable products.

Products that last longer offend almost nobody: reducing the overheads of production in environmental, economic and humanitarian terms. If something can be returned to use after moderate remediation (such as surface treatments), the gains are real from every perspective.

The role of surface treatments

In the past, recycling has tended to mean breaking rubbish back into its constituents, and feeding them back into the production process at the bottom. This can be uneconomic, produce poorer quality products (like recycled toilet paper), and environmentally unhelpful (due to increased energy expenditure or exposure to dangerous chemicals like the mercury and lead in “green” light bulbs).

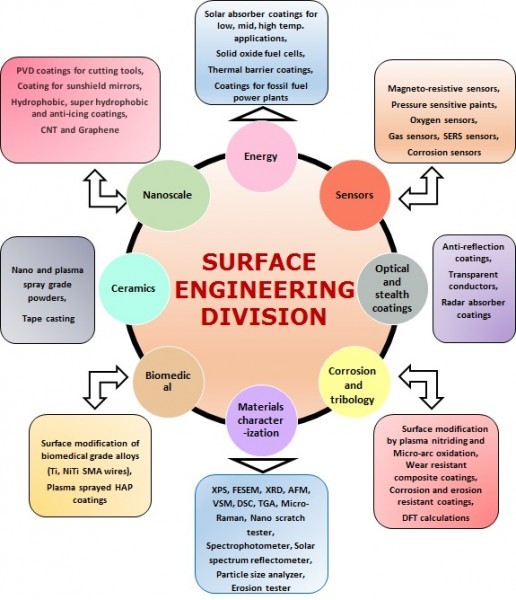

The alternative is to design products for reusability. A reusable product is one that can be remediated at low cost and low risk. This is where specialists in surface treatments come into the picture. Expertly engineered surfaces offer enormous opportunities to extend product serviceability, lower costs and genuinely protect the environment. The opportunities are greatest when the possibilities are explored at the outset of a product’s design.

Even when an item reaches the maximum number of remediations possible within one application’s quality control specifications, it is often possible to re-purpose it in another. For example, energy companies already supply parts retired from oil and gas installations to enterprises engaged in tidal energy and food production.