Have you ever wondered what elastomeric materials are? This term covers a wide variety of elastic or rubber-like materials that are used extensively in every corner of global manufacturing. From the definition to the different types, we take a closer look into the world of elastomeric materials.

Definition of elastomeric

In broad terms, an elastomeric material is one that exhibits any rubber or elastic properties. The material does not need to be made of rubber but generally comprises long chain-like molecules. These materials are categorised by their material type, their compound, and most importantly by their durometer – how hard they are.

Types and their functions

Foam and sponge

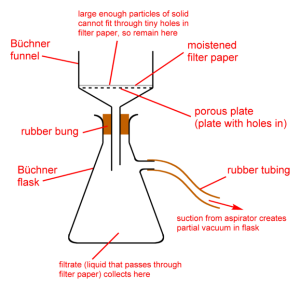

These two are frequently grouped together because they share many attributes, notably the same cellular structure. Lightweight foam enables air to circulate and is used in insulation, cushioning and filtration. Sponge, on the other hand, is made from expanded rubber and has unconnected cells, which means the material does not retain water.

Rubber

Rubber itself is an elastomeric material, of course, and comes in two forms: natural and synthetic. Both are considered a solid elastomeric. There are tens of synthetic rubbers available, including silicone and neoprene, and their uses are widespread in all areas of manufacturing. Silicone can be seen everywhere and is becoming a superior choice for certain products, such as silicone hoses from suppliers such as goodflexrubber.com/pages/silicone-hose-manufacture/.

Both natural and synthetic rubbers are found in specific items. O-rings are one of the most significant but often overlooked elastomeric joining products on earth and are used extensively in many areas of manufacturing to create a seal at a mechanical joint. The flexibility of an O-ring enables the parts to move but stops air or liquid passing through.

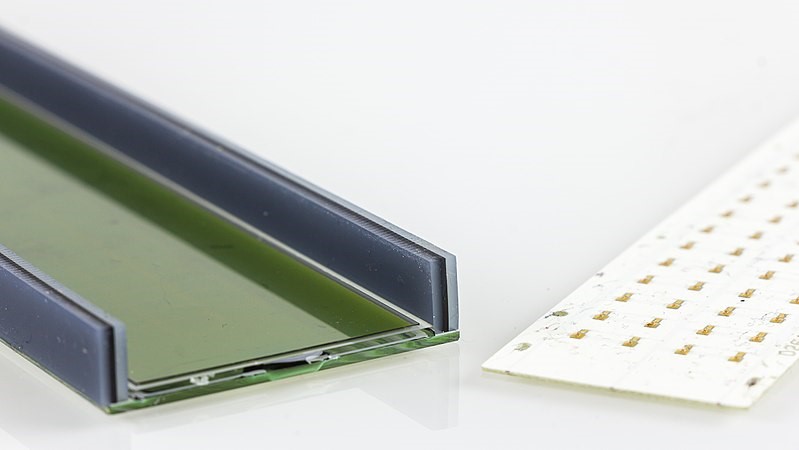

EMI shielding/thermal management

Another two that are frequently grouped together are the synthetic materials used for thermal management and those used for electronic magnetic interference (EMI) shielding. The growth of the use of EMI shielding materials has coincided with the growth of electrical products, in which they are used extensively. These kinds of materials are used to offer flexible solutions to thermal management, air control and EMI shielding.

Elastomeric materials come in both natural and synthetic forms, with both key to the manufacturing of many of the products we use each and every day.