Customizing your powder coating booth is essential for businesses aiming to meet specific operational needs and achieve optimal results. From ensuring precise coating to enhancing efficiency, each modification brings its own set of advantages. Whether you’re working with a small spray paint booth or a large paint spray booth, tailoring it to unique applications can significantly boost your productivity and quality. This blog delves into various customization options and their benefits, providing insights into creating a perfect environment for your powder coating processes.

Tailoring Ventilation Systems for Different Coating Materials

Ventilation is a critical aspect of any powder coating booth. Customizing the ventilation system to match the types of materials you coat can enhance efficiency and safety. For instance, a high-tech spray paint booth with advanced filtration can handle more volatile coatings, ensuring a clean and safe environment. Whether you’re dealing with an industrial spray paint booth or a small spray paint booth, proper ventilation customization reduces contamination and improves the overall quality of the finish.

Integrating Precision Temperature Controls

Temperature control is vital for consistent powder coating results. By integrating precision temperature controls, you can maintain optimal conditions for various coatings. This is particularly important in a high-efficiency spray booth where maintaining consistent temperatures ensures uniform application. Custom spray paint booths with advanced temperature controls can accommodate a wide range of materials, from delicate finishes to robust industrial coatings, enhancing the versatility of your operations.

Customizing Booth Size and Layout for Space Efficiency

Space constraints can impact the efficiency of your powder coating operations. Customizing the size and layout of your booth ensures you make the most of your available space. For example, a mobile spray paint booth can be designed to be compact and portable, ideal for smaller workshops or on-site jobs. On the other hand, a large paint spray booth with an optimized layout can streamline workflows in a larger industrial setting. Customization in size and layout maximizes space utilization and improves operational flow.

Enhancing Lighting for Better Visibility and Precision

Proper lighting is crucial for achieving high-quality powder coating results. Customizing the lighting setup in your booth can significantly impact visibility and precision. A professional spray paint booth with strategically placed LED lights can reduce shadows and ensure even illumination, making it easier to spot imperfections. Whether you’re working in a home spray paint booth or a commercial spray paint booth, enhanced lighting customization can lead to more accurate and consistent coatings.

Adding Modular Components for Flexibility

Modularity allows for flexibility and scalability in your powder coating booth. Customizing your booth with modular components enables you to adapt to changing needs and expand capabilities over time. For example, an affordable paint spray booth with modular walls and racks can be reconfigured to accommodate different sizes of workpieces. This customization offers versatility, making it suitable for a wide range of applications, from small-scale projects to large industrial operations.

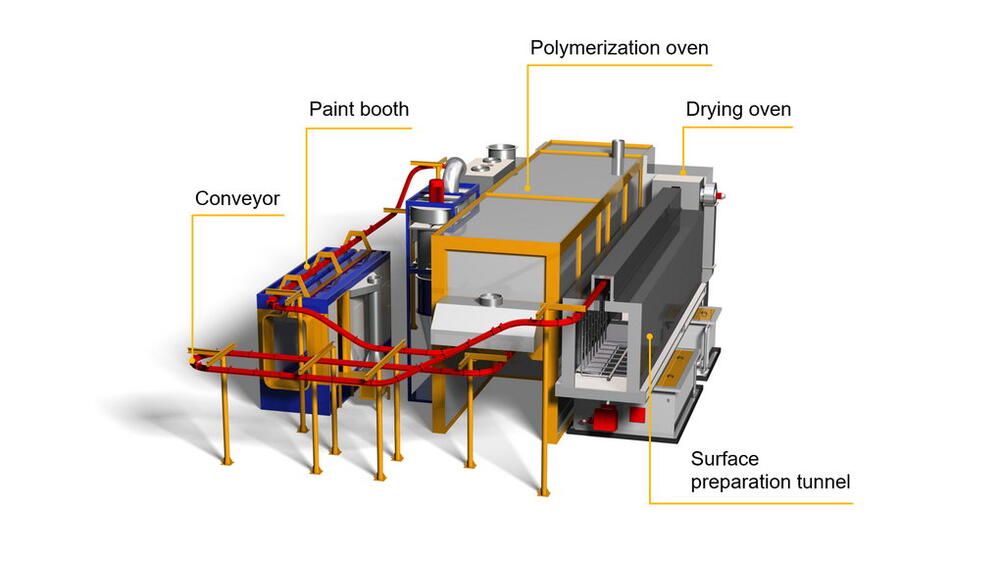

Upgrading to Automated Systems for Efficiency

Automation can significantly enhance the efficiency and consistency of your powder coating processes. Customizing your booth with automated systems, such as robotic arms and conveyors, can streamline operations and reduce manual labor. In a high-efficiency spray booth, automation ensures precise application and reduces the risk of human error. This customization is particularly beneficial in commercial spray paint booths where high throughput and consistency are paramount.

Incorporating Safety Features for Operator Protection

Safety is paramount in any powder coating operation. Customizing your booth with enhanced safety features can protect operators and ensure compliance with regulations. Features such as interlocks, emergency shut-off systems, and fire suppression systems can be integrated into your booth. A ventilated paint spray booth with these safety customizations can prevent accidents and create a safer working environment. This is especially important in settings where hazardous materials are used, such as industrial spray paint booths and blast booths.

Designing for Easy Maintenance and Cleaning

Maintenance and cleaning are essential for the longevity and performance of your powder coating booth. Customizing your booth for easy maintenance can save time and reduce downtime. Features such as easy-access panels, self-cleaning filters, and smooth interior surfaces can simplify the cleaning process. A spray paint booth maintenance plan that includes these customizations can keep your booth in optimal condition, ensuring consistent performance and extending its lifespan.

Creating Specialized Zones for Different Coating Processes

Different coating processes may require unique environments. Customizing your booth with specialized zones for various processes can optimize efficiency and quality. For instance, a powder coating booth with designated zones for pre-treatment, coating, and curing can streamline operations and reduce cross-contamination. This customization is beneficial for complex projects involving multiple coating stages, ensuring each process is performed in the ideal conditions.

Customizing your powder coating booth to suit unique applications can significantly enhance performance, efficiency, and quality. From tailored ventilation systems to advanced automation and safety features, each customization brings its own set of benefits. Whether you’re operating a small spray paint booth or a large industrial spray paint booth, these modifications can help you achieve the best possible results for your specific needs.